In contemporary hospitality architecture, facade design has evolved far beyond surface treatment. It has become a primary tool for shaping spatial ide...

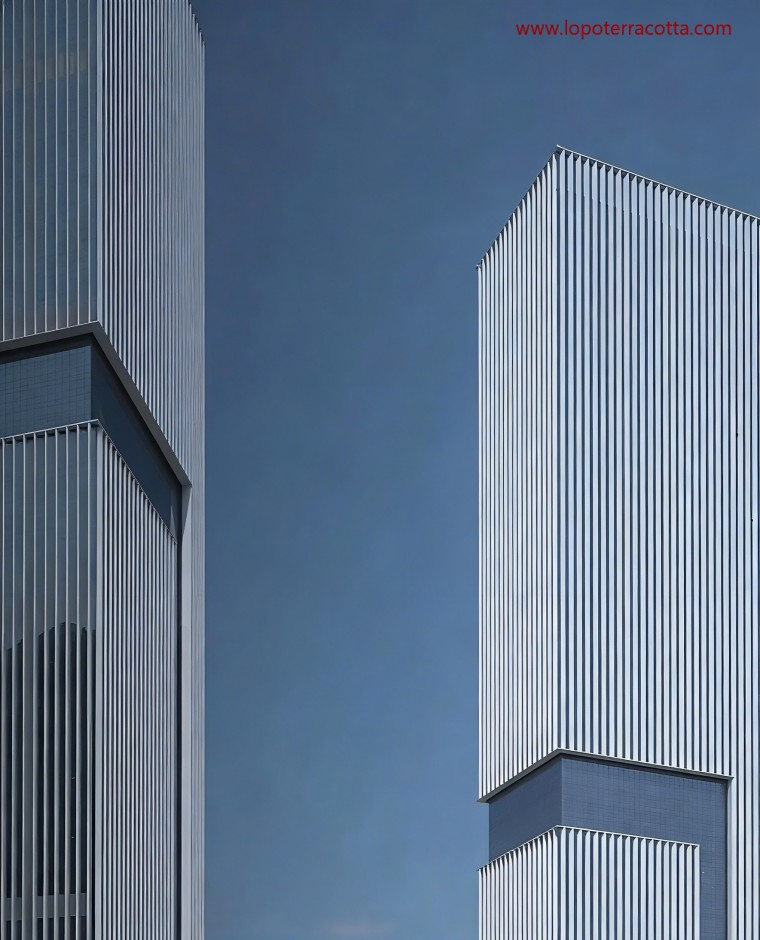

большеThe LACADIERE Skyline in Chengdu represents a rare moment in façade engineering: a super-tall residential tower whose exterior envelope combines techn...

большеNagpur, the “Orange City” of Maharashtra, has emerged as one of India’s most promising tier-2 technology centres. Strategically located at the geograp...

больше

Ceramic materials have long been favored for rainscreen applications, but industry guidelines typically recommend usage below 100 meters due to concerns around panel weight, anchorage tolerances, and pressure differentials in wind zones. The LACADIERE Skyline challenged these assumptions with a façade that more than doubles that height limit.

LOPO Terracotta collaborated with the design team to engineer a system capable of meeting the structural demands of a 200-meter tower. This included:

The resulting façade performs safely under wind load pressures far exceeding those encountered in mid-rise applications.

Chengdu’s climate presents engineering challenges distinct from coastal or desert regions. The city experiences prolonged humidity, abundant rainfall, and seasonal heat spikes due to its basin topography. These conditions shaped both the material and system design for the façade.

Key environmental performance strategies include:

These measures create a building envelope that remains durable under variable environmental stressors while improving occupant comfort.

LOPO Terracotta Panel Corporation engineered the façade components through iterative testing and formula refinement. To meet the project’s stringent performance requirements, the materials underwent:

These processes ensured that the ceramic elements—including Terracotta Wall Panels, Terracotta Facade Panels, and Clay Louvers—would maintain performance integrity over the building’s lifespan.

While the material science behind the façade is complex, the installation process required equal precision. Maintaining consistent vertical alignment across 200+ meters demanded:

This combination of engineered components and controlled installation produced the façade’s signature seamless vertical rhythm.

Beyond the rainscreen surface, the façade incorporates shading and ventilation components designed for occupant comfort and energy efficiency. The LOPO Terracotta Baguette profiles and Terracotta Louvers act as passive shading devices that reduce solar heat gain, particularly on exposures receiving intense western sunlight.

These linear ceramic elements also enhance façade depth and shadowing, contributing to visual definition without adding mechanical complexity.

A significant goal of the façade engineering strategy was to reduce long-term operational costs. Terracotta is naturally resistant to staining and weathering; its low-porosity surfaces minimize maintenance requirements. Combined with a ventilated cavity and controlled drainage, the façade reduces water streaking and prevents moisture accumulation behind the cladding.

Lifecycle benefits include:

The LACADIERE Skyline project demonstrates that ceramic materials—when engineered for advanced performance—can meet and exceed the demands of super-tall construction. Through technical precision, height-specific adaptations, and climate-responsive detailing, the façade merges reliability with expressive vertical form.

At the center of this achievement is LOPO Terracotta Panel Corporation, whose material development, testing, and fabrication enabled the project to operate beyond the boundaries of conventional terracotta applications.

For future super-tall buildings seeking durable, culturally grounded, and environmentally responsive envelopes, this project offers a model of how ceramic technologies can evolve to meet contemporary engineering challenges.

China Terracotta Panel & Terracotta Baguette Project | Architectural Terracotta Facade

This project utilizes high-quality terracotta panels and baguettes, enhancing the modern aesthetic and durability of the architectural facade.